John Deere Sprayer High-clearance option provides 1.93 m (76 in.) of ground clearance

|

|

|

|

Spraying tasseled corn

|

|

|

|

|

Additional height provided by lift castings

|

|

|

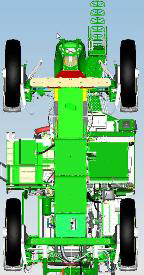

The high-clearance bundle consists of four assemblies (one per wheel) that attach between the chrome spindle and the casting that houses the wheel motor. These castings are designed to give the sprayer an additional 406 mm (16 in.) of clearance while still allowing the wheels to be set at 3.05 m (120 in.) when the tread setting is all the way in.

By providing an offset design, the operator can drive down 762-mm (30-in.) rows with the existing machine. The bundle also includes additional crop shielding, hose extensions, and items needed to make commonly used solution system functions more accessible to the operator.

The following information is a detailed list of parts included along with descriptions of shielding and other essential parts.

|

|

|

|

Lift structures

|

|

|

|

|

|

Structures to lift sprayer

|

|

|

|

|

Lift casting contents

|

|

|

Lift castings are designed to give operators an additional another application with existing sprayers. These castings fit between the current wheel motor housing and chrome spindle, as shown in the picture.

Installation of the castings can be done in approximately four hours, but more time will be needed to add additional shielding and to make commonly-used functions of the machine more accessible.

NOTE: Lift castings should only be used with model year 2008 and newer machines.

|

|

|

|

Shielding

|

|

|

|

|

|

Grill shielding

|

|

|

|

Grill shielding is included in the bundle and is designed to keep pollen and tassels from reducing airflow through the grill. The front crop deflector is designed to move the crop to either side of the grill while the integrated screen shields debris from the cooling package.

It is recommended that the shield be installed prior to running in tall crops since leaves, pollen, or other debris could be drawn into the cooling package.

|

|

|

|

Operator entry

|

|

|

|

|

|

Increased height on hinge point

|

|

|

|

Entry ladder modifications bring the hinge point out of the crop while the ladder is folded and moving through the field. Two additional steps are included in the bundle to lower the first step while the ladder is in the unfolded position.

For the fuel-fill ladder on the left side of the machine, a removable extension will be provided to make fueling more convenient. When the removable extension for fuel fill is not being used, it can be conveniently stored just below the storage compartment.

|

|

|

|

Under-frame shielding

|

|

|

|

|

|

Belly shields

|

|

|

|

Current belly shielding will continue to be offered to protect hoses, electrical connections, and other essential elements of the sprayer from damage. The belly shielding is also intended to create a smooth surface under the machine to allow for smooth crop flow as the sprayer travels through the field.

If belly shielding is required, it can be added by ordering a field-installed bundle.

|

|

|

|

Wheel shields

|

|

|

|

|

|

Sprayer equipped with wheel shields

|

|

|

|

To maximize productivity and minimize crop damage in 762-mm (30-in.) rows, wheel shields are highly recommended for use in tall corn or other tall crops. Wheel shields help prevent damage from the wheels, hubs, and tires as the sprayer moves through the field by providing a smooth surface for the crop to flow past the sprayers wheel package.

Without wheel shields, the hubs can contact crop and cause damage to the ears and stalks.

|

|

|

|

Solution system

|

|

|

|

|

|

Eyewash extension

|

|

|

|

|

Eductor extension

|

|

|

Solution system changes included in the bundle improve the accessibility of key components when the high-clearance bundle is installed.

The eductor bracket can be used to lower the eductor by 406 mm (16 in.) to a more accessible height when loading the machine.

The eyewash tank is equipped with a longer hose and relocated on/off valve to allow for safe rinsing, if needed.

|

|

|

| |