| |

|

| Introducing the 2730 Combination Ripper |

|

|

|

|

|

|

Delivering on customer needs

Performance

- Customizable residue management with hydraulically adjustable 660-mm (26-in.) disk blades that are either individually mounted or in a gang configuration

- Complete compaction layer fracture through entire soil profile with ripper shanks set on 610-mm (24-in.) side-to-side spacing

- Improved residue flow with greater ripper point spacing front to back

- Preferred field finish with knife edge and round bar baskets or a coil tine harrow

Uptime

- The industry’s largest frame provides added durability to reduce downtime

- The 2730 features 77 percent fewer grease points than the competition

- Stubble damage resistant and higher floatation 445/50R tires deliver 33 percent more footprint to the ground

Cost of operation

- The 2730 integrates four operational areas into one system reducing overall tillage system costs and increasing asset utilization

- Independently adjustable disk, ripper, and leveling systems

- Maintenance-free components

|

|

| |

|

| Customer value |

| |

|

The 2730 Combination Ripper has been designed to meet customer’s intensive tillage needs. The industry-leading frame size and durability delivers the performance and reliability to handle the most challenging field conditions.

The overall machine design was built off market place needs to operate in higher residue levels and leave a customizable field finish which creates the ideal soil environment to maximize yield potential. The 2730 is available in 4.30-, 5.50 -, 6.70-, and 7.90-m (14-, 18-, 22-, and 26-ft) working widths. The 2730 delivers a 44 percent increase in productivity over the previous John Deere 2700 Mulch Ripper.

The 2730 delivers on customer needs through maintenance-free components, fewer grease points, and larger, more durable tires. These points add exceptional value to the machine which cannot be matched by the competition.

|

|

| |

|

| Larger working widths |

| |

The 2730 Combination Ripper is available in the following machine configurations:

|

Model

|

Working width

|

Transport width

|

Transport height

|

|

7S24 Rigid – Individual blades

|

4.27 m (14 ft)

|

6.07 m (19 ft, 11 in.)

|

2.49 m (8 ft, 2 in.)

|

|

7S24 Rigid – Disk gangs

|

4.27 m (14 ft)

|

5.74 m (18 ft, 10 in.)

|

2.49 m (8 ft, 2 in.)

|

|

9S24 Rigid – Individual blades

|

5.49 m (18 ft)

|

6.86 m (22 ft, 6 in.)

|

2.49 m (8 ft, 2 in.)

|

|

9S24 Rigid – Disk gangs

|

5.49 m (18 ft)

|

6.86 m (22 ft, 6 in.)

|

2.49 m (8 ft, 2 in.)

|

|

9S24 Folding – Individual blades

|

5.49 m (18 ft)

|

5.82 m (19 ft, 1 in.)

|

3.30 m (10 ft, 10 in.)

|

|

9S24 Folding – Disk gangs

|

5.49 m (18 ft)

|

5.82 m (19 ft, 1 in.)

|

3.35 m (11 ft, 0 in.)

|

|

11S24 Folding – Individual blades

|

6.71 m (22 ft)

|

5.59 m (18 ft, 4 in.)

|

3.81 m (12 ft, 6 in.)

|

|

11S24 Folding – Disk gangs

|

6.71 m (22 ft)

|

5.69 m (18 ft, 8 in.)

|

3.81 m (12 ft, 6 in.)

|

|

13S24 Folding – Individual blades

|

7.92 m (26 ft)

|

5.59 m (18 ft, 4 in.)

|

4.39 m (14 ft, 5 in.)

|

|

13S24 Folding – Disk gangs

|

7.92 m (26 ft)

|

5.69 m (18 ft, 8 in.)

|

4.19 m (13 ft, 9 in.)

|

|

|

| |

|

| Reduced tillage system costs |

| |

The 2730 is a combination ripper that integrates four operational areas into one system. These four areas consist of disk blades, ripper shanks, rear closing disks, and leveling attachments. The ability to quickly and conveniently customize these components independently offers reduced cost of operation and maximum productivity.

The disk blades eliminate the need for multiple residue sizing passes into one single pass that reduces surface residue levels by 60 to 80 percent. The ripper shanks accomplish full hardpan fracture across the entire soil profile with their 610-mm (24-in.) spacing in order to create a porous air and water environment for root development.

Along with the ripper shank’s side-to-side spacing, it also features a 1270-mm (50-in.) fore-aft spacing, which improves residue disbursement and contributes to the machines nearly plug-proof performance. With the walking tandem action, the closing system can follow the contour of the ground and eliminate plugs leading to a more consistent finish. To achieve optimal field levelness and clod sizing, the operator can control the rear leveling attachment with in-cab, hydraulic controls. |

|

| |

|

| Customizable residue management |

| |

Hydraulically-adjustable disk blades

|

|

Hydraulic adjustment cylinder

|

|

|

Larger 660-mm (26-in.) disk blades are hydraulically adjustable and are set in a tandem-type configuration. The disks are available in either individual disk blades or gang type configuration. The front and rear blades are set at an 18-degree angle on either 460-mm (18-in.) spacing for individual or 280-mm (11-in.) spacing for gang to provide an aggressive disking action.

The disks can be adjusted in-cab to be raised completely out of the ground or lowered to a maximum in-ground depth of 203 mm (8 in.). The disk blades operate in constant down-pressure and the optimal operating depth can be set using stop collars on the hydraulic cylinder. The ability to independently adjust the front disks based on varying conditions allows the operator to optimize desired residue sizing and mixing. |

|

| |

|

| Larger Walk-Over™ tandem wheels |

| |

Walk-Over tandem wheels

|

|

|

|

Walk-Over tandem wheels with larger tire options offer maximum support, stability, and flotation in the field. The staggered wheel design provides additional room for residue flow and obstacles while also providing a consistent working depth in uneven ground.

Available tires options are listed below:

|

Model

|

Mainframe tire

|

Wing frame tire

|

|

7-standard 4.30 m

(14 ft) rigid

|

12.5L-15 FI F LR*

340/65R18 Goodyear®

445/50R22.5 Re-Tread

445/50R22.5 New

|

-

|

|

9-standard 5.50 m

(18 ft) rigid

|

340/65R18 Goodyear*

445/50R22.5 Re-Tread

445/50R22.5 New

|

-

|

|

9-standard 5.50 m

(18 ft) folding

|

340/65R18 Goodyear*

445/50R22.5 Re-Tread

445/50R22.5 New

|

-

|

|

11-standard 6.70 m

(22 ft) folding

|

445/50R22.5 Re-Tread*

445/50R22.5 New

|

12.5L-15 FI F LR Goodyear*

340/65R18 Goodyear

|

|

13-standard 7.90 m

(26 ft) folding

|

445/50R22.5 Re-Tread*

445/50R22.5 New

|

12.5L-15 FI F LR Goodyear*

340/65R18 Goodyear

|

*Base tire option |

|

| |

|

| Superior residue flow |

| |

2730 ripper shanks buried in ground

|

|

|

|

The 2730 delivers improved residue flow by increasing the overall frame length and underframe clearance along with the fore-aft spacing of the ripper shanks.

The 1270-mm (50-in.) fore-aft spacing maximizes residue disbursement and 953 mm (37.5 in.) of underframe clearance contribute to the machines nearly plug-proof performance. The 2730 features 610-mm (24-in.) side-to-side spacing which accomplishes full hardpan fracture across the entire soil profile to create a porous air and water environment for root development and plant nutrient uptake. |

|

| |

|

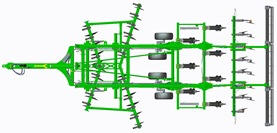

Overhead view of 7-standard layout

|

|

|

|

Maintenance-free components reduce downtime

Sealed, maintenance-free bearings on the 2730 Combination Ripper results in reduced downtime for the operator. |

|

| |

|

Maintenance-free polymer bushing

|

|

|

|

The new, greaseless bearings increase productivity by reducing the amount of time needed to service the 2730 before operation and allowing operators to spend more of their valuable time in the field. The maintenance-free bearings have been extensively field tested to stand up in tough conditions providing longer bearing life.

The 2730 features 77 percent fewer grease points than major competitors resulting in less, time-extensive maintenance and improving field productivity by up to 7.5 acres per day. |

|

| |

|

| Preferred field finish |

| |

Hydraulic knife-edge rolling basket

|

|

|

|

The 2730 comes equipped with the optional hydraulically adjustable leveling attachments to achieve the desired field finish. The hydraulic rolling baskets can be set to three hydraulically-controlled positions from the comfort of the cab. The heavy-duty coil tine harrow is rigid mounted to the frame and depth adjustments are made according to the rear closing disk system. Based on field finish needs, the 2730 less harrow option is also available.

The leveling attachments come in a round-bar, knife-edge, or coil tine configuration and prepares field for a reduced amount of secondary tillage passes before planting.

The increased capabilities of this combination ripper will take the 2730 to the next level in meeting the ever-changing needs of our customers while offering exceptional reliability and value.

Summary

The John Deere 2730 Combination Ripper gives customers more productivity through larger machine size offerings and increased residue flow. More uptime is realized with 77 percent fewer grease points than competitors and the maintenance-free components means less time spent on service and repairs. The 2730 multi-functional design reduces overall tillage system costs through less passes. The 18 percent larger disk blades aggressively size and bury residue, ripper shanks shatter yield limiting compaction, and the leveling attachments leave the preferred field finish for one seedbed preparation pass.

For more information on the 2730, refer to the Ag Sales Manual.

Goodyear is a U.S.-registered trademark of Goodyear Tire & Rubber Company. |

|

| |

|

|

| |

| Effective Date : 20-Aug-2014 |

|

|

Product features are based on published information at the time of publication and are subject to change without notice. All

trademarked terms, including John Deere, the leaping deer symbol and the colors green and yellow used herein are the property

of Deere & Company, unless otherwise noted. Availability of products, product features, and other content on this site may

vary by model and geographic region.

Engine horsepower and torque information for non-Deere engines are provided by the engine manufacturer for comparison purposes only.

Actual operating horsepower and torque will be less. Refer to the engine manufacturer's Web site for additional information. |

|

| |

|

| Copyright © 1994-2015 Deere & Company. All Rights Reserved. |

|

|

|

|

|