John Deere S Series Combine Settings

| Optimization John Deere S-Series Combines: harvesting high-moisture corn |

Harvesting high-moisture corn approximately 25 percent and up, creates its own unique set of challenges versus harvesting dry corn.

Wet corn can affect combine capacity, losses, and grain quality unless adjustments and configuration changes are made because of the differences when harvesting high-moisture corn.

The information provided will assist operators to successfully adjust or configure their John Deere S-Series Combines when harvesting high-moisture (wet) corn by listing the steps, starting at the front of the combine and working through the combine, similar to crop flow.

Feederhouse

- Drum position-Up

- Conveyor speed-slow (small sprocket)

Feed Accelerator

Speed: low speed: 450 rpm

NOTE: Optional feed accelerator (BH84655) for extra high quality, such as popcorn or food corn. Slow speed drive reduces standard two-speed drive from 450/800 rpm to 320/770 rpm.

Feed accelerator type

TriStream™ standard corn, beans, and small grain

NOTE: Use BH84653 smooth wear strips for feed accelerator for extra high corn quality for excessive grain damage.

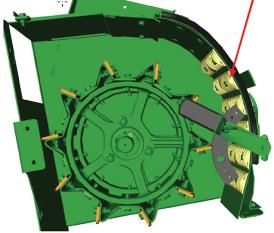

TriStream rotor

15 threshing elements are installed in the standard configuration for high-moisture corn harvest.

NOTE: If grain damage is present, elements of row one and two can be changed into smooth elements.

Row one: Order one AH216674 (bundle contains three elements),

Row two: Order one AH216675 (bundle contains three elements).

NOTE: If row one and two are changed for extremely high corn quality, please also change the wear strips at the feed accelerator BH84653. These elements are generally required if there is excessive wear with the factory-installed rotor or have rice threshing elements.

NOTE: Material handling may be affected in green tough straw and green stemmed soybeans.

The smooth elements in the illustrations above are available in kit AH167739.

Concave

It is important to understand the relationship of the concave and rotor when harvesting high-moisture corn. The concave threshes and the rotor separates.

Round bar is the preferred concave for harvesting high-moisture corn since its overall performance is very good in high-moisture and green residue.

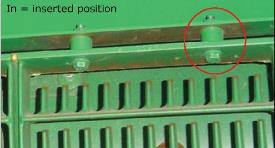

Concave setting

Generally, the diameter of the cob is a good initial setting for the concave clearance. If the concave clearance is too wide or closed too tight, cracks and brokens may increase.

Rotor should be set as slow as possible and concave should be set as open as possible. Reduced losses and chipped cobs will be the result. If losses are excessive, increase the rotor speed. For kernels left on cobs, tighten concave.

NOTE: Only make one adjustment at a time.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|