News Information

What is With Planter Unit Upforce?

04/12/2024

When it comes to downforce decisions on the planter, some producers may ask, “What about upforce?”

John Deere Planter

Read Story

John Deere Operations Center Spring Training

03/21/2024

Check Out the Latest How To Videos from John Deere For this Spring. Using Work Planner, How to Create Boundaries

John Deere Operations Center

Read Story

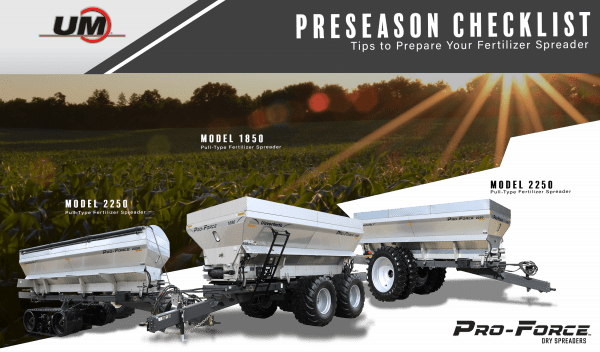

Unverferth ProForce PreSeason Prep

03/07/2024

The right preparation ensures that your equipment runs smoothly when the narrow application window arrives. Use this checklist to help prepare your Pro-Force dry spreader for the upcoming spring application season.

Unverferth Equipment

Read Story

2024 John Deere Spring Clinic March 12 8:15-11:30

03/04/2024

2024 John Deere Spring Clinic March 12 2024 8:15-11:30 @ Cross Implement 703 S Minier Ave Minier IL

Planter & Tractor PreSeason Service Tips | New See & Spray Technology | 8R with Autonomy Prep G5 Display & 7500 Receiver | Operations Center Updates | Product Improvements & Retrofit Options

John Deere Customer Event

Read Story

John Deere See & Spray Sprayer Demos Spring 24

02/03/2024

Reachout to Your SalesPerson to Signup One of Your Fields for a John Deere Sprayer See & Spray Demo This Spring.

There is Limited Availablity and the Field Must be Located in Tazewell, Logan or...

John Deere Sprayer

Read Story

Deere Compact Track Loader Onboard Grade Indication

01/29/2024

Industry-exclusive Onboard Grade Indication option on the Deere Compact Track Loader is available through the factory or field kit and provides cross-slope (roll) and main-fall slope (pitch) of the machine within the in-cab monitor display.

Commercial Worksite

Read Story

John Deere Spring Parts Catalog 2024

12/02/2023

John Deere Parts Catalog Spring 2024 PreSeason Saving on Parts, Equipment, Supplies, and More

John Deere Parts

Read Story

John Deere 7000 Receiver

03/03/2023

The StarFire™ 7000 Receiver offers a new correction level with accuracy like RTK Radio. The SF-RTK correction level provides 2.5-cm (1-in.) horizontal accuracy without the need for additional hardware. This is an improvement of 17 percent from the previous generation of StarFire receiver with SF3. The SF-RTK signal uses two additional satellite constellations (BeiDou and Galileo) as well as both GPS (United States) and GLONASS (Russia) satellites.

John Deere Precision Ag

Read Story

Checkout Relevant Software Updates for Spring 2023

02/27/2023

Make Sure Your John Deere Displays are Up to Date for the Upcoming Spring Season

John Deere Precision Ag

Read Story

John Deere Gator Attachment Configurator

02/23/2023

Looking for Attachments for Your John Deere Gator? Save Now on Select John Deere Attachments.

John Deere Gator

Read Story